Innovation and tested quality: the centre of technological excellence

Flex2000 is fully dedicated to development and research, using the most advanced technology available.

The laboratories are equipped with cutting-edge resources to ensure that Flex2000 provides polyurethane flexible foams and pocket springs of the highest quality to its customers.

Flex2000, with six dedicated laboratories, reaffirms its absolute commitment to raising quality standards in the polyurethane flexible foam and pocket spring industry. Each laboratory plays a crucial role in the strict control of all raw materials, manufacturing processes, and final products, ensuring that every stage of production meets the most demanding quality and safety criteria.

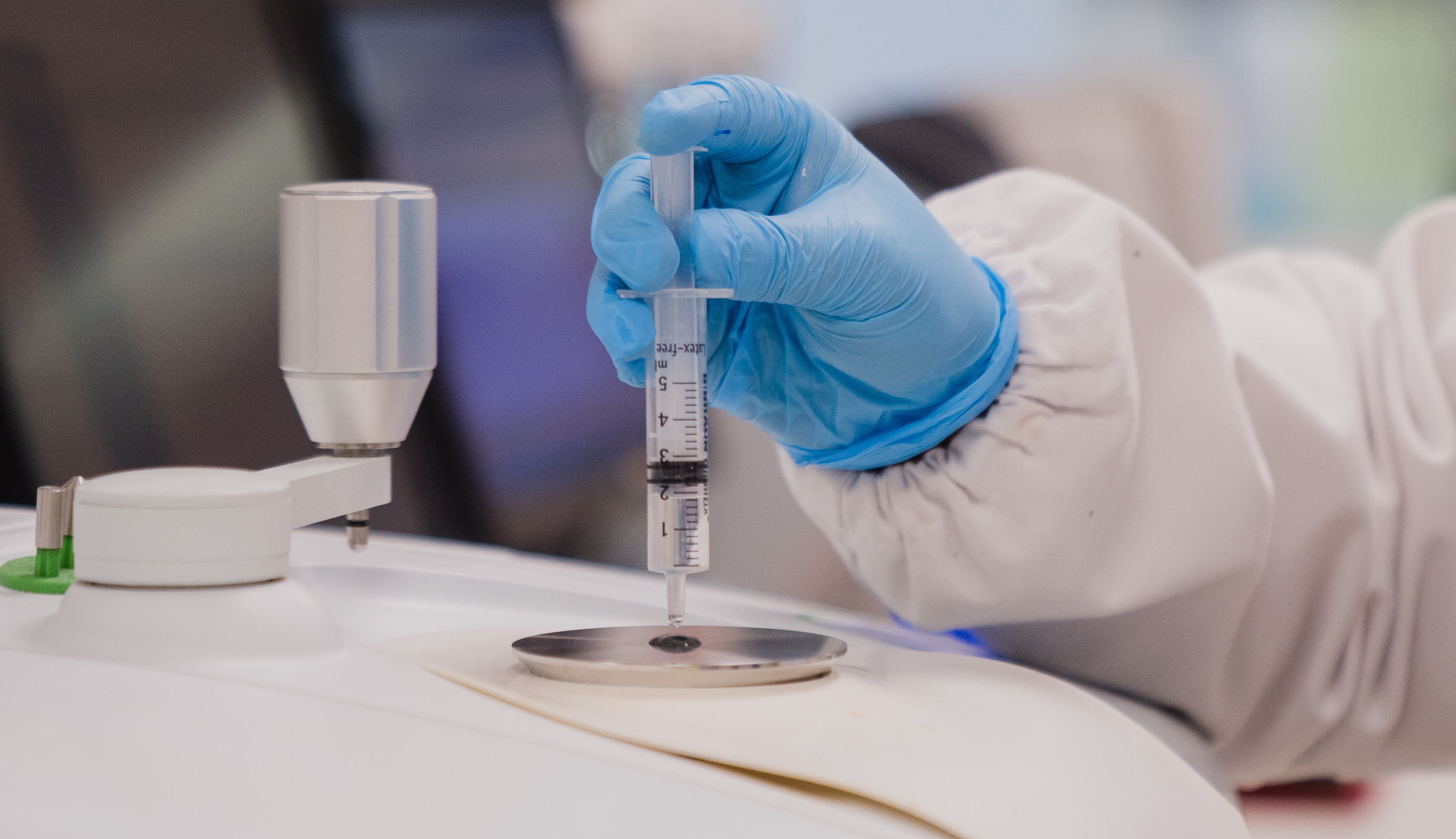

In the Chemical Laboratory at Flex2000’s foam unit, meticulous tests and analyses are conducted on all raw materials and developed products. This laboratory is essential for ensuring that every component used in foam production strictly adheres to established standards, guaranteeing consistency and excellence in the final products.

Control begins upon the receipt of raw materials: a sample is immediately taken and sent to the laboratory for detailed analysis. Only after approval by the chemical team, who operate under strict safety protocols, is the material unloaded and used in production. This process ensures that only superior quality materials enter the production line, minimising the risk of variations and ensuring the reliability of the products.

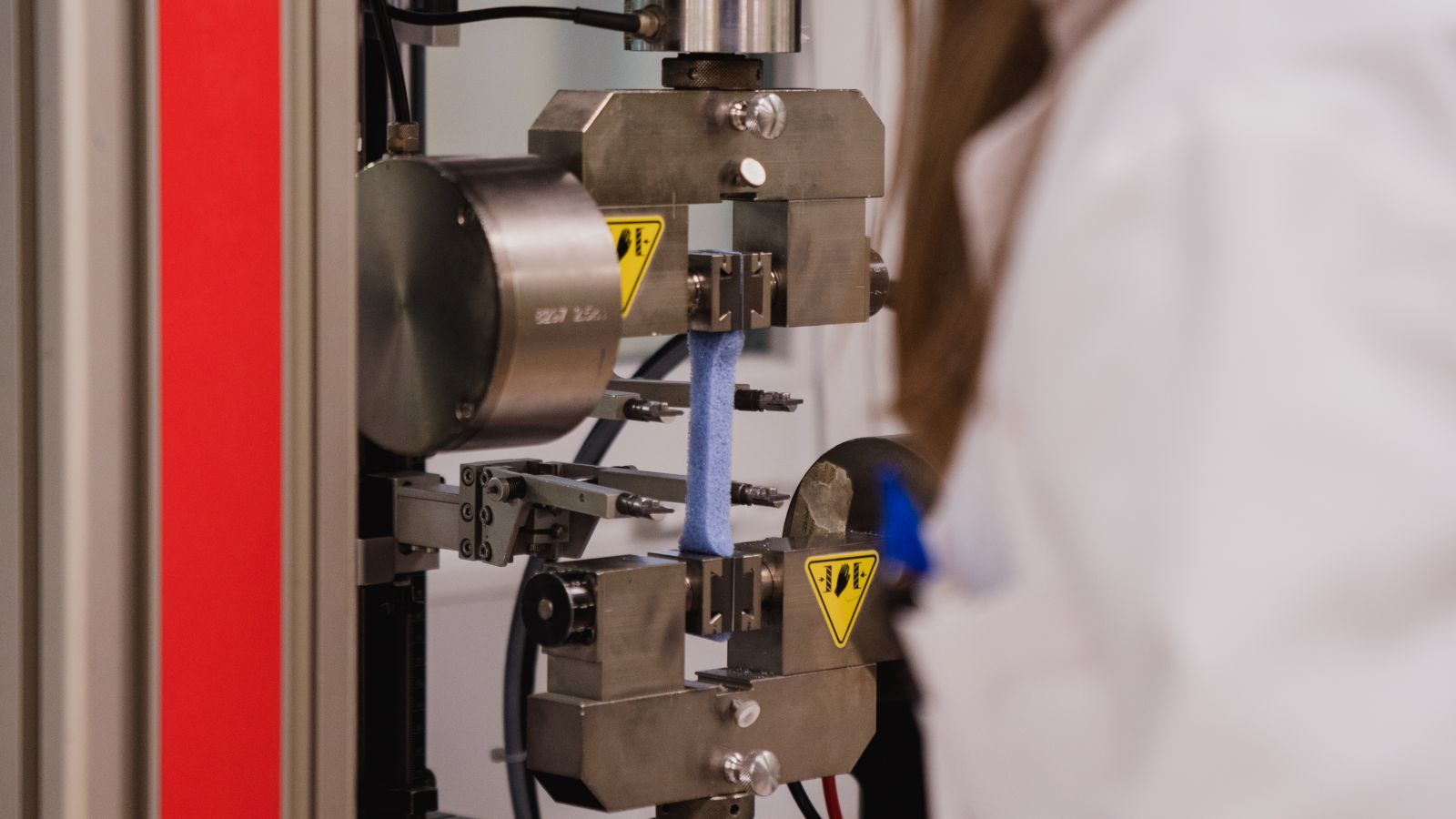

The Physical Laboratory at Flex2000 is the hub for evaluating the physical properties of the foams produced. Here, rigorous tests are conducted to assess critical characteristics such as density, strength, durability, and performance under various conditions. This laboratory ensures that the foams not only meet but exceed market expectations, offering products that combine superior performance and longevity.

In the industry, strict physical control is vital to ensure that the foams perform consistently across various applications, from furniture to automotive and construction. Flex2000 invests in cutting-edge technology to carry out these evaluations, staying aligned with the latest market trends and demands.

_crop_66f6c30d01cc4.jpg)

Flex2000 is committed to ensuring that each mattress developed meets the highest quality standards, offering consumers the best possible sleep experience.

(1).jpg)

The I+D Laboratory is the innovation hub at Flex2000. The team in this laboratory is constantly exploring new technologies and materials, focusing on creating advanced solutions that meet the dynamic demands of the market.

Innovation in the foam and mattress industry is not just about following trends; it’s about anticipating customer needs and delivering products that not only meet but exceed expectations. Flex2000 positions itself as a leader by continuously investing in research and development, ensuring that innovation remains at the heart of its offerings.

Combustibility Laboratory

At Flex2000, safety and strict adherence to international standards are fundamental pillars.

Modified Combustion (CM) and Fire Retardant (FR)

Our combustibility laboratory, fully dedicated to the control of modified combustion (CM) and fire retardant (FR) foams, ensures that each batch produced meticulously meets the safety standards required by various markets.

Crib V Standard (BS 5852)

For the United Kingdom, we conduct tests in accordance with the Crib V standard (BS 5852), ensuring that our foams are in full compliance with local regulations.

California 117 Standard (TB 117:2013)

In the United States, for certain states, we follow the California 117 standard (TB 117:2013), ensuring that our products meet the strict fire resistance requirements.

Certification NI 9175 e BZ

CM and FR Foam Testing

Quality and Safety

Our combustibility laboratory reflects Flex2000's ongoing commitment to quality and safety, ensuring that our partners can trust our products to meet the needs of the most demanding markets.

With the expansion into the pocket spring sector, Flex2000 upholds its unwavering philosophy of rigor and quality. The new unit, Pockee, includes a laboratory exclusively dedicated to controlling raw materials and the final product. This laboratory, equipped with cutting-edge technology, ensures that the pocket springs produced maintain the excellence that defines the Flex2000 brand.

In the pocket spring industry, quality control is vital to guarantee that each spring functions perfectly, providing support and durability over time. Flex2000 applies the same rigor and attention to detail that has made it a leader in foam production, ensuring that its pocket springs stand out for their superior quality.